PROMETAF

Programmable metainterfaces for friction control

This project was funded by ANR through Grant

ANR-18-CE08-0011

Project summary

Although the

optimization of the devices involving functional contacts would enable

significant energy savings, at the beginning of the project, there was no

established method to prepare an interface with pre-defined frictional

properties. The aim of PROMETAF has been to propose a simple and generic

surface design strategy to obtain such interfaces.

The idea has been to build surfaces with a

deterministic texture, by placing model asperities, one by one, on a deformable

substrate. By tuning the shape and altitude of each individual asperity, we

have been piloting the macroscopic behaviour of the

interface, while targeting unprecedented frictional properties. In practice we

have explored various types of interfaces giving access to various pre-defined,

non-linear friction laws, some of which connecting working conditions usually

considered incompatible.

This newly accessible toolbox is expected to be useful

to advance the state-of-the-art, both by questioning the usual approach to

friction control through homogeneous surface coatings, and by extending the

range of applications of metamaterials to friction.

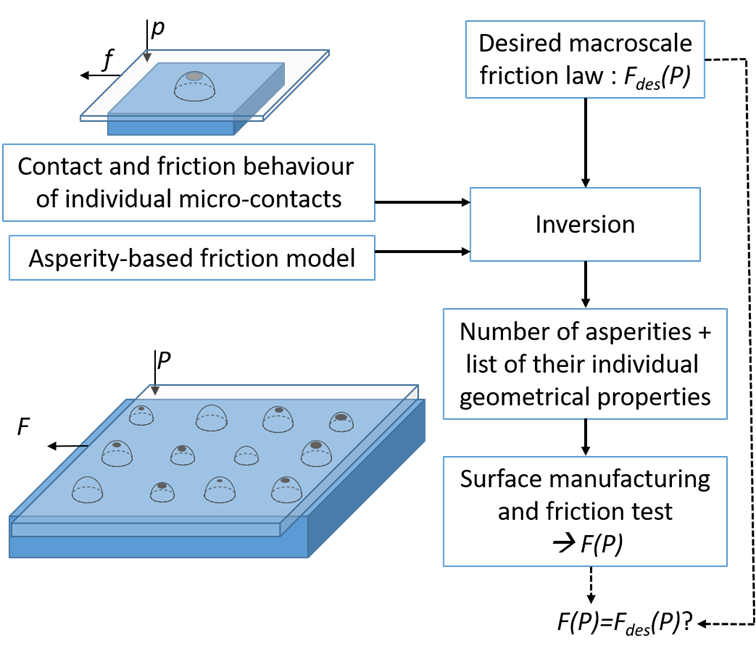

To validate a new interface design, the following

three main methods are used.

First, we identify the relevant multi-asperity model,

based on a preliminary calibration of the tribological

behavior of a single microcontact. The model is then

inverted, to predict the list of geometrical descriptors of all individual

asperities (radii of curvature, altitudes) that is expected to provide the

desired macroscale frictional behavior. In this project, we used analytical

inversions.

Second, we fabricate an elastomer substrate according

to surface topography prescribed by the inversion. We prepare an aluminum mold

decorated by an array of spherical holes with the prescribed individual depths,

and use it to obtain a polydimethylsiloxane (PDMS) substrate with the negative

topography: an array of spherical asperities.

Third, we form a contact between the textured PDMS and

a smooth glass substrate, and perform mechanical tests in order to measure the

friction law of the interface (friction force vs normal force). The

experimental friction law is finally compared quantitatively to the desired

one.

Using the above methods, we validated various original

interface designs. Those include: (i) interfaces

whose friction laws passes through three operating points usually considered as

incompatible, (ii) interfaces whose friction coefficient can be tuned on-demand

and (iii) interfaces featuring two different friction coefficients according to

the range of normal force applied to the contact.

Illustration of the design strategy

Flowchart of the design strategy. Upper

sketch: single microcontact submitted to a normal

force p and a friction force f. Lower sketch: metainterface

submitted to normal and friction forces, P and F. Black ellipses: real contact

regions.

Outputs of the project

Publication in

peer-reviewed international journals

[1] E. Delplanque, A. Aymard,

D. Dalmas, J. Scheibert. Solving curing-protocol-dependent shape errors in PDMS

replication. Journal

of Micromechanics and Microengineering 32, 045006 (2022)

(link, pdf)

Oral communications in international conferences

[1]

J. Scheibert. Approche modèle en tribologie :

application aux contacts élastomères secs. Journées

Internationales Francophones de Tribologie 2021. Distanciel.

Invited conference

[2]

A. Aymard. Friction law

of model asperity-based rough elastomer contacts. Contact Mechanics International Symposium 2022, Chexbres,

Switzerland

[3] J. Scheibert.

Shear-induced contact

morphology changes in rough elastomer interfaces. Contact Mechanics International

Symposium 2022, Chexbres, Switzerland. Invited conference

[4] A. Aymard.

Design and realization of metasurfaces with tunable

friction law. 7th World

Tribology Congress, Lyon, France

[5] J. Scheibert.

Creating soft interfaces with pre-defined static friction forces. 9th International Tribology Congress, 2023,

Fukuoka, Japan. Invited conference

Oral communications in national conferences

[1] A. Aymard. Realisation of surfaces with controlled friction

laws. 17èmes Journées de la Matière

Condensée 2021, Rennes, France

[2]

E. Delplanque. Résolution des erreurs de forme dépendantes du protocole de

durcissement, lors de la réplication par du PDMS. Journée 50 ans du groupe français des polymères, 2021, Lyon, France

(poster)

[3]

J. Scheibert. Frictional metainterfaces. Journée

« Soft metamaterials » du GDR MEPHY,

2023, Paris, France